Magazine

< back

Interview to Emanuele Trombettoni, Chief of Aluminium and Slate metal Processing dpt

We interviewed Emanuele Trombettoni to understand what it means to be Chief of Aluminium and Slate metal Processing dpt.

-

Could you tell us what’s your role and what are your main tasks?

My role consists in managing and coordinating the main manufacturing phases: from the transformation of raw materials into semi-finished products, until the packing of finished products of the various collections. I receive our customer orders from the Production planning office,and take care of the entire manufacturing process. -

Can you tell us how did you get here at Inoxa and how was your career path?

I came from a completely different field: I worked as salesman in the real estate sector. For me it was a complete change, a gamble both for myself and for the company that trusted me. I was hired as an employee in the moulding department and then became the Head of that dpt. Later, I had other roles and, for almost 2 years now, I have been the Chief of Aluminium and Slate metal Processing dpt. -

What does it mean to be Chief of Aluminium and Slate metal Processing dpt in a company like Inoxa?

The aluminium and metal sheet processing department is growing rapidly, so it is definitely motivating to be in charge of this department. Furthermore, the addition of the new lines Ipnos and Zenith, for wardrobe and bathroom, and the Murano collection has been stimulating. There are many phases that make up our articles: on one hand is certainly a commitment to follow all the manufacturing process, but it is equally gratifying to see the final result. -

What are the values in your daily work that you share with Inoxa?

We try to offer our customers a service tailored to their needs, following our values: speed of response and quality of the items offered. Within our department, I deeply care about the collaboration and involvement of all colleagues: I like that everybody feels to be part of a team. -

Is there an Inoxa product assembled in your dpt. that you prefer?

All of them are the best in their market field. However, the latest Murano items, in my opinion, have a particular charm and aesthetics. -

Ikona and Hyper are two key collections of the Inoxa range. What do you think are their respective strengths?

I would say that they are equivalent from a technical point of view. Ikona items strengths applies to the material with which they are made and to its spare versatility. Hyper items fit perfectly into a modern context, with clean and essential lines. -

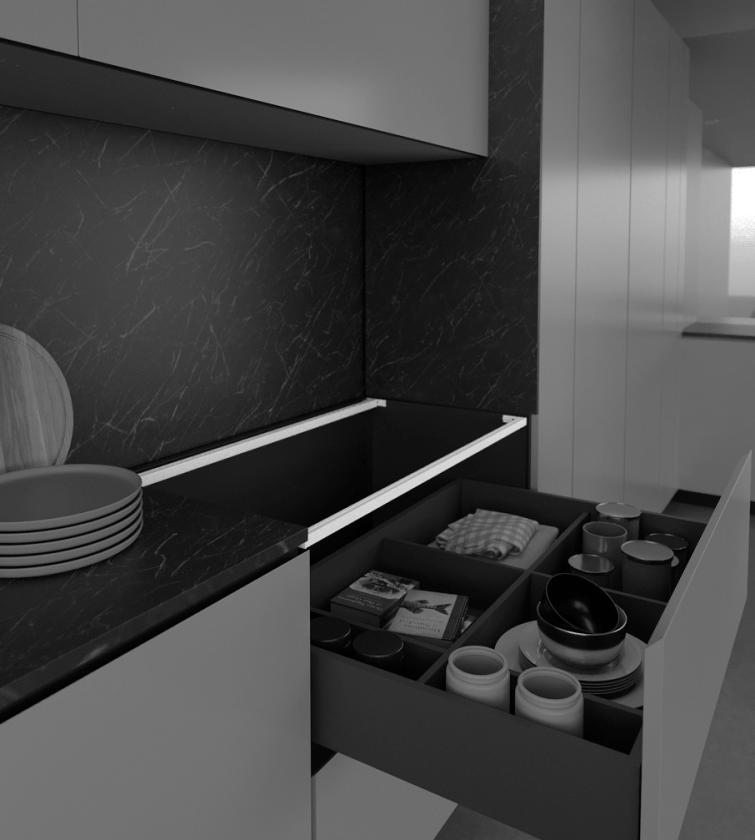

What do you think are the essential characteristics of the kitchen of the future?

There is never enough space available in a “crowded” environment such as the kitchen room. In my opinion, the kitchen of the future must have every space exploited to the fullest. The accessories we produce point in that direction: to make the most of every single space.